Laboratory Energy Hub

Our laboratory is part of the Montilivi Campus of the University of Girona, located in the capital city of the Girona province. The lab surface is of 72 m2 and is part of the research facility with total surface of 4,071 m2.

The energy system that feeds the lab, in terms of both electricity and thermal energy has been designed as an energy hub for experimentation on energy efficiency management. The overall system is being managed with storage capabilities (batteries and thermal tank) to improve flexibility in the management and increase energy efficiency.

Environment monitoring

There are 16 workstations in the lab and the energy used by each workstation is monitored individually with a wireless sensor network. Moreover, the lab is equipped with the following sensors to measure the air quality and environmental conditions:

- 3 interior temperature sensors

- 1 exterior temperature sensor

- Athmosferic pressure

- Humidity

- Noise sensor

- CO2

- 2 Light sensors

- Vibration sensor

- 2 motion sensors

- occupancy detection

- door and windows open/closed sensors

These sensors are combined with the app allowing users for expressing their comfort sensation at the workplace. The information provided is being collected with the objective to adjust the conditions and improve the users’ comfort on the one hand and find out the relation between the comfort and energy consumption, on the other.

Moreover, the energy hub can also benefit from a weather station located in the Campus with the following parameters:

- Temperature

- Humidity

- Solar irradiance

- Atmospheric pressure

- Precipitation

- Wind speed

- Wind direction

Components of the energy hub

Electricity supply

Power from the grid is complemented with two photovoltaic installations.

Photovoltaic installation 1:

A total of 14 solar panels (3.92 kWp, 3.7 kWn) connected to a 4 kWh battery. Thus, PV panels supply electricity to part of the lab allowing also to charge the battery. The photovoltaic solar plant connected to the low voltage network (permanent power supply, red sockets, LO) has the following characteristics:

- Three-phase system.

- 14 modules (Canadian Solar CS6K-280P)

- Dimensions of the module: 1650 x 992 x 40 mm

- Rated power of the module: 280 Wp

- Efficiency: 17.11%

- Estimated energy produced: 5,970 kWh/year

- Installed power: 3.92 kWp

- Rated power: 3.7 kW

And the battery installed:

- Sonnen Batterie eco 8.0/4

- Usable battery capacity: 4.0 kWh

- Rated inverter power (charging/discharging): 2,500 W

- Three-phase battery.

Photovoltaic installation 2:

A total of 12 solar panels with microinverters (4.5 kWp) connected to a 7 kWh battery. Thus, PV panels supply electricity to part of the lab allowing also to charge the battery. The photovoltaic solar plant connected to the low voltage network (normal power supply, white sockets, LN) has the following characteristics:

- 12 modules (Sunpower SPR-P3-375-BLK-AC)

- Dimensions of the module: 1690 x 1160 x 35 mm

- Rated power of the module: 375 Wp

- Efficiency: 19.1%

- Installed power: 4.5 kWp

- Single-phase system.

And the battery installed:

- Enphase IQ Battery Mono 2x3T 7 kWh

- Usable battery capacity: 7 kWh, 2,56 kW

- Single-phase battery

Thermal supply

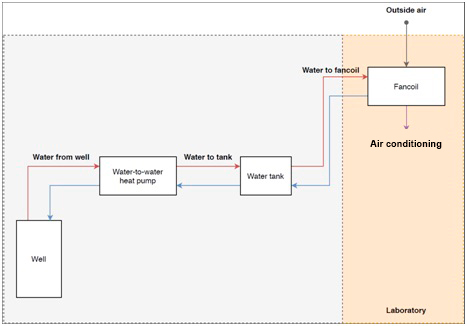

Space heating and cooling is guaranteed by a ground sourced water-to-water heat-pump that incorporates an inertial water tank to store the conditioned water and a fan-coil to conditionate the air.

The geothermal system has the following features:

- Geothermal well depth: 100m

- Heat pump model: Clausius Classic

- Heat pump electric consumption power: 0,8-3.3 kW

- Heat pump thermal supply power: 3-15 kW 0-35ºC

- COP (nominal): 4.61

- Inertia water tank: 100 lts

- water-air heat-exchange: Fancoil

The water tank can be used to provide flexibility to the energy lab. When generation of PV panels is available, the heat pump can produce the thermal energy needed and store it within the water tank.

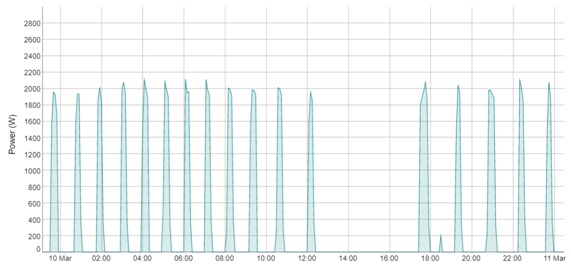

The heat pump consumption is monitored by a power sensor that sends data to our database every 5 minutes. In that way, it can be observed the cycles of consumption according to the temperature losses of the water tank, the configurated tank temperature setpoint and the office temperature setpoint. In the example of 10th March shown below, it’s visible that during midday the heat pump did not consume, coinciding with the hours with higher temperature.

Goals of the energy hub

On one hand, this installation will allow the eXiT lab to reduce its dependency of the power grid and the use of fossil fuels from the building’s heating system. On the other hand, eXiT research group will take profit of this installation developing and testing software tools for an optimal scheduling of the generation and storage resources, minimizing the dependence of the lab on the grid or minimizing the costs taking into account energy tariffs.

The main capacities of the infrastructure are:

- Charge and discharge testing

- Environmental and air quality evaluation

- Users comfort monitoring and evaluation based on objective sensor data and users’ subjective data

- Energy usage monitoring

- Evaluation of relations between energy usage and environmental conditions

- Evaluation of relations between energy usage and users’ comfort

- Forecasting of PV generation and energy demand

- Modelling thermal demand according inside/outside temperature

- Modelling heat-pump thermal production and efficiency according to water tank and office temperature setpoints

- Optimal scheduling of storage assets

- Energy Hub modelling and optimisation

- Optimal control of HVAC assets

- Non-intrusive load monitoring studies

For more information: